I-Zhongdi ZD-8917 2 ku-1 Soldering and Desoldering Station 90W, Max 350W

1. Izincazelo

I-ZD-8917 Soldering & Desoldering Station iyisiteshi esisebenza kahle kakhulu futhi esisebenza ngezinto eziningi esakhiwe futhi senzelwe ucwaningo lomkhiqizo we-elekthronikhi, ukukhiqizwa nokusebenza kabusha.Leli thuluzi lisetshenziswa emikhakheni yocwaningo lwe-elekthronikhi, ukufundisa nokukhiqiza, ikakhulukazi ekulungiseni nasekusetshenzweni kabusha kwezinto zikagesi kanye nemishini yokuxhumana.

1.1 Iyunithi yokulawula

I-soldering iron kanye ne-desoldering gun ithuluzi kulawulwa ngokuzenzakalelayo ngama-micro-processors amabili.Ama-electronics okulawula idijithali kanye nenzwa yekhwalithi ephezulu kanye nesistimu yokushintshisana ngokushisa iqinisekisa ukulawulwa kwezinga lokushisa okunembile ethiphu le-soldering.Izinga eliphakeme kakhulu lokunemba kwezinga lokushisa kanye nokuziphatha okushisayo okushukumisayo okuhle kakhulu ngaphansi kwezimo zomthwalo kutholwa ukuqoshwa okusheshayo nokunembile kwamanani alinganisiwe kusiyingi sokulawula esivaliwe, futhi lo mklamo ungowobuchwepheshe bokukhiqiza obungenamthofu.

Ibanga lokushisa ngu-160-480 ℃.

1.2I-Soldering Iron(ZD-418)

I-ZD-418 soldering iron enamandla angu-60W (Isilinganiso sokushisa esingu-130W) kanye namathiphu okuthengisa ayisipele (uchungechunge lwe-N9) angasetshenziswa noma yikuphi emkhakheni wezogesi.

Amandla aphezulu kanye nomklamo omncane wenza le iron ifanelekele umsebenzi omuhle wokusoda.Isici sokushisa senziwe nge-PTC futhi inzwa eseceleni kwe-soldering ingalawula izinga lokushisa le-solder ngokushesha nangokunembile.

1.3 Desoldering gun (ZD-553)

I-ZD-553 Desoldering gun esinamandla angu-90W (Isilinganiso sokushisa esingu-200W) kanye namathiphu okuqeda amandla (uchungechunge lwe-N5) singasetshenziswa noma yikuphi emkhakheni wezogesi.

Amandla aphezulu kanye nomklamo wohlobo lwesibhamu kwenza lesi sibhamu sifanelekele umsebenzi omuhle we-desoldering.Isici sokushisa senziwe nge-PTC futhi inzwa eseqenjini le-desoldering ingakwazi ukulawula izinga lokushisa le-desoldering ngokushesha nangokunembile.

2. Imininingwane

Amandla kagesi: AC100-240V 50/60Hz

Amandla: 140W

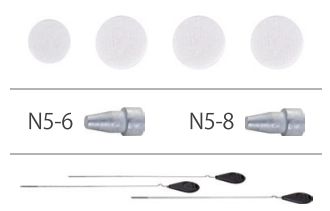

Izingxenye ezisele ezingezansi zifakiwe

Spare soldering iron&desoldering gun

| Imodeli | Amandla kagesi | Amandla | Qaphela | I-heater | Ithiphu |

| I-ZD-418A (i-soldering iron) | 24V | 60W (Isilinganiso sokushisa ngu-130W) | 4 izikhonkwane, awukho umsebenzi wokulala | 78-4181 | N9 |

| I-ZD-418B (i-soldering iron) | 24V | 6 izikhonkwane, ngomsebenzi wokulala | |||

| ZD-553A (desoldering isibhamu) | 24V | 90W (Isilinganiso sokushisa esingu-200W) | 6 izikhonkwane, awukho umsebenzi wokulala | 78-5531 | Inani eliphakeme kakhulu lama-N5 |

| I-ZD-553B (desoldering isibhamu) | 24V | 7 izikhonkwane, ngomsebenzi wokulala |

3. Ukusebenza

3.1 Beka i-ayina e-soldering kanye nesibhamu e-desoldering esibambi ngokuhlukana.Bese uxhuma ipulaki endaweni yokudonsa esiteshini bese ujika ngokwewashi ukuze uqinise ipulaki nati.Qiniseka ukuthi ukunikezwa kwamandla kuhambisana nokucaciswa kwepuleti lohlobo futhi iswishi yamandla isendaweni ethi "VALIWE".Xhuma iyunithi yokulawula endaweni yamandla bese uvula amandla.Bese kuzozihlola wena lapho zonke izici zokubonisa zizovulwa kafushane.Isistimu ye-elekthronikhi ibe isizivulela ngokuzenzakalelayo izinga lokushisa elimisiwe futhi ibonise leli nani.

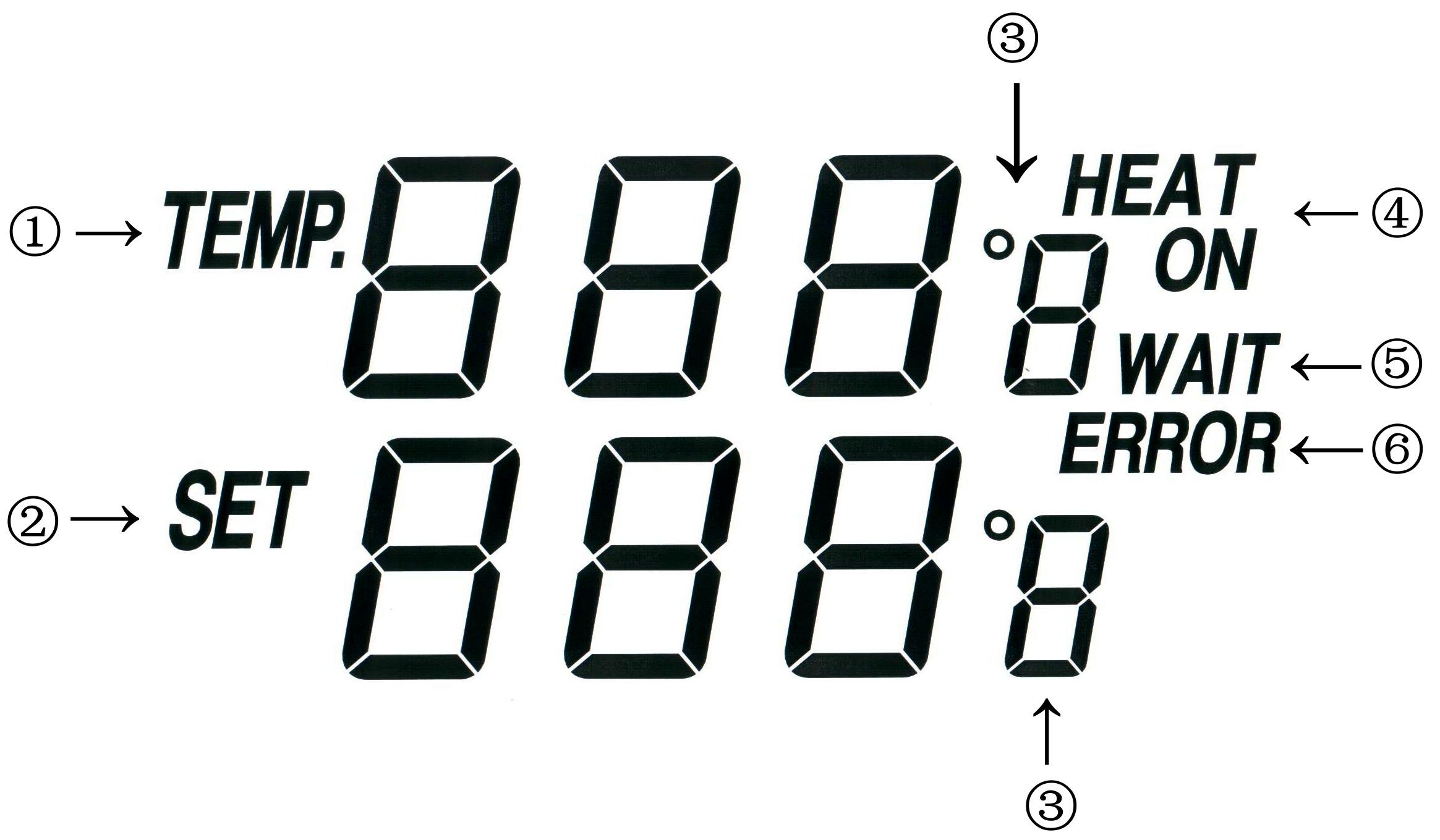

3.2 Isibonisi kanye nokusetha izinga lokushisa

① Ibonisa izinga lokushisa langempela lethiphu .

② Ibonisa izinga lokushisa lokusetha.Cindezela inkinobho ethi “PHEZULU” noma “PHANSI” ukuze usethe izinga lokushisa.

③ ℃/℉ isibonisi.Cindezela inkinobho ethi “℃/℉” ukuze ushintshe isibonisi phakathi kuka-℃ no-℉.

④ Uma izinga lokushisa langempela lethiphu liphansi kunokulungiselelwa, kuzovela okuthi “HEAT ON”.

⑤ Uma umehluko ungaphezu kuka-±10℃ phakathi kwamazinga okushisa angempela nokusetha ithiphu, okuthi “LINDA” kuzovela.Linda ize inyamalale.

⑥ Uma "ERROR" ibonakala, kungase kube khona inkinga ngesistimu.Noma isibhamu se-soldering iron/desoldering asixhunyiwe kahle.

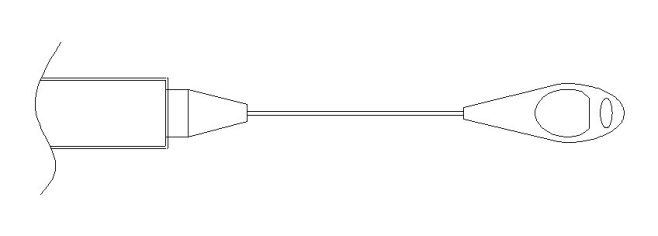

4. Ukuhlanza i-tube desoldering

Ngemuva kokusetshenziswa, imfucuza ye-solder ishiywe epayipi.Hlanza njalo, ngaphandle kwalokho imfucuza izovimba isibhamu sokuqothula.Emazingeni okushisa aphezulu, imfucumfucu ye-solder izokhipha i-oxidize (i-solder engenawo umthofu iyancibilika ku-220 ℃ futhi isolder elinomthofu liyancibilika ku-180℃), likhukhumale futhi linamathele eshubhuni ngokuqinile.Ekugcineni kuzocishe kube nzima ukususwa ngisho nangethuluzi lokuhlanza elinjengangezansi.

(Ithuluzi lokuhlanza)

Indlela yokuhlanza:

Ngemuva kokusetshenziswa ngaso sonke isikhathi, qalisa isibhamu sokuqothula izikhathi ezingu-3-5 emoyeni ngokushesha ukuze usule imfucuza ye-solder ngaphakathi kwepayipi layo.

Uma isikhawu phakathi kokusebenza ngakunye singaphezu kwemizuzu engama-20, sebenzisa ithuluzi lokuhlanza ukuhlanza ipayipi ngezikhathi ezithile.

Lapho ukusebenza kwe-desoldering kuba mpofu, sebenzisa ithuluzi lokuhlanza ukuhlanza ipayipi ngokushesha.

Lapho ingxenye yeshubhu yengilazi igcwele imfucumfucu ye-solder, ihlanze ngokushesha.

Uma isihlungi siyavaleka, shintsha isihlungi ngokushesha.

5. Imodi yokulala

Nge-4-pin soldering iron & 6-pin desoldering gun, ayinayo imodi yokulala;

Ine-6-pin soldering iron & 7-pin desoldering gun, inemodi yokulala.

Isiteshi sizongena kumodi yokulala uma singasetshenziswa imizuzu engu-15.Izinga lokushisa lethiphu lizophola lifike ku-200℃ futhi liyigcine phakathi nesikhathi sokulala kuze kube yilapho isiteshi siqalwa kabusha.Futhi isiteshi sizobuyela kuzilungiselelo zangaphambilini ngemuva kokuqalwa kabusha.Ungasebenzisa noma yiziphi izindlela ezingezansi ukuze uyiqale kabusha:

● Ivale bese uyivula.

● Cindezela noma iyiphi inkinobho (Uma ungayithathi i-ayina e-soldering emizuzwini emibili ngemva kokucindezela inkinobho, isiteshi sizobuyela kumodi yokulala futhi).

● Thatha i-soldering iron/deldering gun.

| Iphakheji | Ubuningi/Ibhokisi | Usayizi we-Carton | NW | GW |

| Ibhokisi lesipho | 1 isethi | 36*29*26cm | 5kgs | 6kgs |